While the frozen food industry offers undeniable convenience and global reach, ensuring product freshness throughout the supply chain remains a critical hurdle. Here, packaging and delivery play a pivotal role. Balancing cost-effective choices with optimal temperature control during storage and transport significantly impacts revenue and customer satisfaction.

Frozen Research International has shown that even slight temperature fluctuations above -10°C in frozen chicken nuggets can trigger fungal growth on their surfaces. This not only leads to spoilage and economic losses, but also poses a potential health risk due to mycotoxin production.

This blog post dives deeper into the importance of these aspects, exploring strategies to optimise frozen food packaging and delivery.

How Packaging Impact on Frozen Food Quality?

Maintaining quality throughout the frozen food supply chain hinges heavily on effective packaging. While freezing itself slows down microbial growth and enzymatic activity, it can also impact food quality. Here’s how packaging plays a crucial role:

#1. Minimising Ice Crystal Damage

Large ice crystals during freezing can damage food tissue, leading to “drip loss” (liquid release) upon thawing. This occurs as water within muscle fibres (myofibrils) gradually moves out into the surrounding space between the cells (extracellular space). Selecting the right packaging material can help control ice crystal formation and size, potentially minimising this issue.

#2. Extending Shelf Life

Packaging materials with specific gas permeability characteristics can influence oxygen levels within the package. Oxygen exposure accelerates spoilage based on:

- Oxidation: When exposed to oxygen, the fats and oils in food undergo a process called oxidation. This breaks down the molecules in the fats and oils, leading to a rancid smell and off-flavours.

- Promoting Microbial Growth: Oxygen can also create an environment favourable for certain types of bacteria and mould to grow. These microbes can degrade the food, leading to spoilage and potential health risks.

The key takeaway is that the longer food is exposed to oxygen, the greater the chance of spoilage due to oxidation and microbial growth.

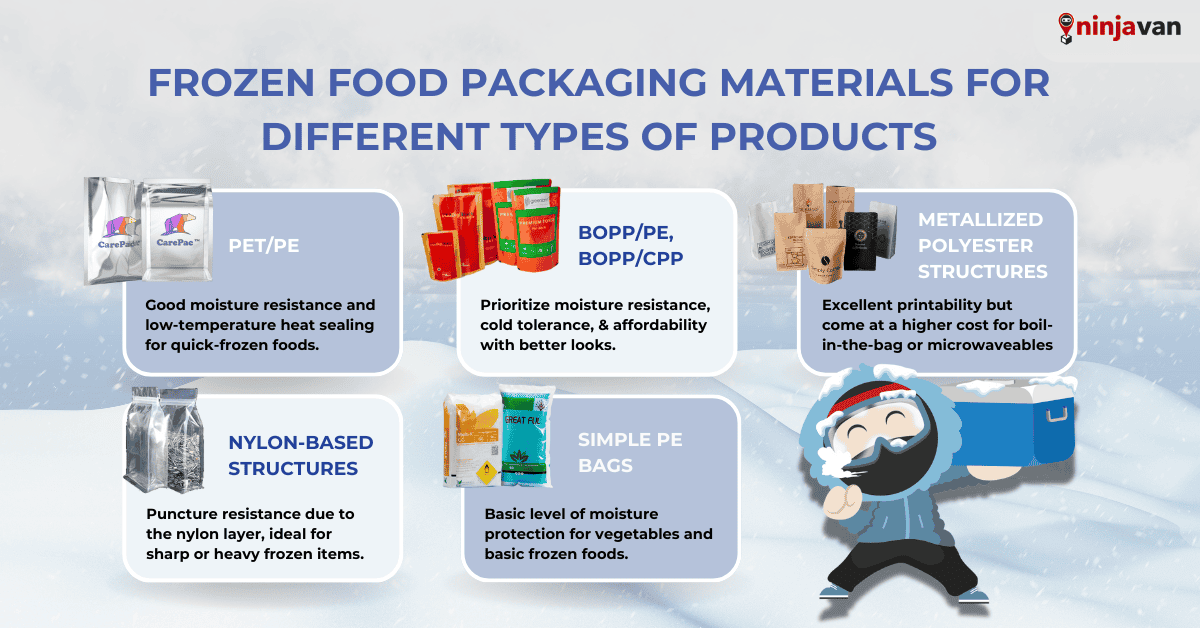

Choosing the Suitable Frozen Food Packaging Materials for Different Types of Products

The ideal packaging material for frozen food depends on several factors, including the product itself and cost considerations. Here’s an overview of some widely used options:

#1. PET/PE

This cost-effective option offers good moisture resistance and low-temperature heat sealing properties, making it popular for quick-frozen foods—blueberries, strawberries, corn, peas, shrimp, scallops; or poultry, like individual chicken breasts.

#2. BOPP/PE, BOPP/CPP

These structures prioritise moisture resistance, cold tolerance, and affordability, with BOPP/PE offering a more aesthetically pleasing appearance compared to PET/PE. Suitable for similar products like fruits, vegetables, seafood or poultry.

#3. Metallized Polyester Structures (PET/VMPET/CPE, BOPP/VMPET/CPE)

These boast excellent printability but come at a higher cost due to the aluminium layer. Their low-temperature heat sealing performance can be slightly weaker. Some products that can be considered to use this type of packaging include boil-in-the-bag or microwaveable frozen product packaging.

#4. Nylon-based Structures (NY/PE, PET/NY/LLDPE, etc.)

These offer exceptional puncture resistance due to the nylon layer, making them ideal for sharp or heavy frozen items. However, their cost is higher compared to other options.

#5. Simple PE Bags

These are typically used for vegetables and basic frozen foods like cauliflower rice, turkey meatballs and fish patties, offering a basic level of moisture protection.

#6. Blister Trays

Frozen food requiring additional shaping or protection—dumplings, salads, ready-to-bake-muffins, and others—often utilises blister trays. Polypropylene (PP) is the most common material for these trays due to its hygiene and low-temperature durability (-30°C).

#7. Corrugated Cartons

For general transportation packaging, corrugated cartons provide cost-effective protection against shock and pressure, making them a popular choice for outer packaging of frozen food. Its built-in cushion absorbs impact and minimises damage to delicate items—pre-cooked frozen food, frozen pizzas, frozen cheese, frozen bread, and more.

Cold Chain Logistics: How to Ensure Freshness During Deliver?

As a business owner in the frozen food industry, you understand the importance of maintaining product quality from your warehouse to the freezer aisle in the marketplace or outlets. This is where cold chain logistics comes into play.

Cold chain logistics refers to the meticulous management of temperature-sensitive products throughout the supply chain. It encompasses everything from storage and transportation to handling and monitoring, all with one crucial goal: ensuring products reach their destination fresh, safe, and at peak quality.

Unfortunately, disruptions in the cold chain can have devastating consequences, and the early signs of a bad cold chain delivery service can be detected as early as the first three deliveries. Here are some red flags to watch out for:

- Damaged packaging

- Inconsistent temperatures

- Late deliveries

These issues not only affect your bottom line due to spoilage, but also damage your reputation and customer satisfaction. Though there is not much you can do to fix the situation if you work with the same logistics provider. However, finding yourself a reliable cold chain partner is a quick win for everything good!

Here’s where a reliable cold chain partner like Ninja Cold can make all the difference. The right cold chain partner can offer you with:

- Temperature-controlled solutions: Refrigerated, chilled, or frozen options to suit your specific needs.

- Advanced monitoring systems: Real-time tracking ensures your products stay within the optimal temperature range.

- Diverse routing systems: Efficient delivery routes minimise travel time and temperature fluctuations.

By partnering with a cold chain specialist, you gain peace of mind knowing your products are in good hands. This translates to reduced spoilage, enhanced customer satisfaction, and brand reputation protection.

Want to learn more? Contact us today, or click on the banner below to talk to our experts and see how Ninja Cold can provide you with customised solutions.

Checklist: How to Distribute Frozen Foods the Right Way!

Frozen food freshness is paramount! Here’s a checklist to ensure your frozen food reaches its destination in peak condition:

#1. Partner with a Reliable Cold Chain Logistics Provider

Look for a partner with a proven track record of maintaining optimal temperatures throughout the supply chain. Consider their reach too as a wider network, such as spanning Southeast Asia allows for broader market access without compromising freshness. You might also need to consider a partner that offers cost-effective options tailored to your specific needs, whether it’s specialised packaging or dedicated storage facilities.

#2. Choose the Right Temperature Control

Different frozen foods require different temperatures. Typically, a good cold chain logistics partner would have multiple temperature control. By selecting the right temperature zone, you ensure your frozen food arrives ready to impress your customers.

For example, Ninja Cold offers a range of controlled environments:

- 15°C to 20°C: Ideal for moderately chilled items like fresh herbs or some fruits.

- 0°C to 5°C: Perfect for preserving freshness of vegetables, meats, or pre-made salads.

- -15°C to -20°C: Ultra-cold for frozen goods like seafood, meats, and ice cream.

#3. Opt for Complete Cold Chain Services

A comprehensive cold chain solution goes beyond temperature control. You need to consider a provider that offers:

- Refrigerated Transportation: A fleet of dedicated refrigerated trucks and vans maintains precise temperatures during transit.

- Real-time Tracking: Monitor your shipment’s progress and temperature 24/7 with some sort of a unified dashboard or an advanced tracking system for ultimate peace of mind.

- Warehousing and Storage: Network of strategically located temperature-controlled warehouses across Southeast Asia can provide flexibility for short-term or long-term storage needs, especially when you’re scaling your business within Malaysia or SEA.

- Customs Clearance Expertise: Working with an experienced team simplifies the often-complex customs process for perishable goods, ensuring smooth cross-border shipping.

By following this checklist and partnering with a reliable cold chain provider like Ninja Cold, you can ensure your frozen food distribution is optimised for freshness, quality, and customer satisfaction.

They Trust Ninja Cold for Frozen Food Freshness

- MBG FruitShop: “Ninja Cold’s extensive network allows us to deliver fresh, seasonal fruits nationwide with confidence.”

- PAfood: “Maintaining peak quality for our delicious frozen meals is crucial. Ninja Cold’s expertise ensures our food arrives restaurant-ready.”

- Lee’s fandbee: “Keeping our ice cream perfectly chilled requires a reliable partner. Ninja Cold’s temperature-controlled solutions are second to none.”

Don’t Compromise on Quality! Experience the Difference

Why choose Ninja Cold? With Ninja Van’s proven track record in the 3PL industry, Ninja Cold leverages years of experience and extensive logistics expertise to create customised cold chain solutions specifically for frozen food distribution. We understand the delicate balance between temperature control, cost-efficiency, and timely delivery.

Our commitment to innovation and exceptional service ensures your frozen food reaches its destination in peak condition, ready to tantalise your customers. Ready to unlock the full potential of your frozen food business?

Get a free quote here and see how Ninja Cold can help your business!

By taking advantage of this free quote, you’ll gain a personalised consultation with our cold chain specialists. They’ll assess your specific needs and design a cold chain strategy that optimises both freshness and cost-effectiveness for your frozen food distribution.