The Red Sea Crisis has recently become a significant concern, especially affecting global supply chains. This article explores the crisis’s impacts and how businesses can navigate these challenges.

The Red Sea Crisis Explained

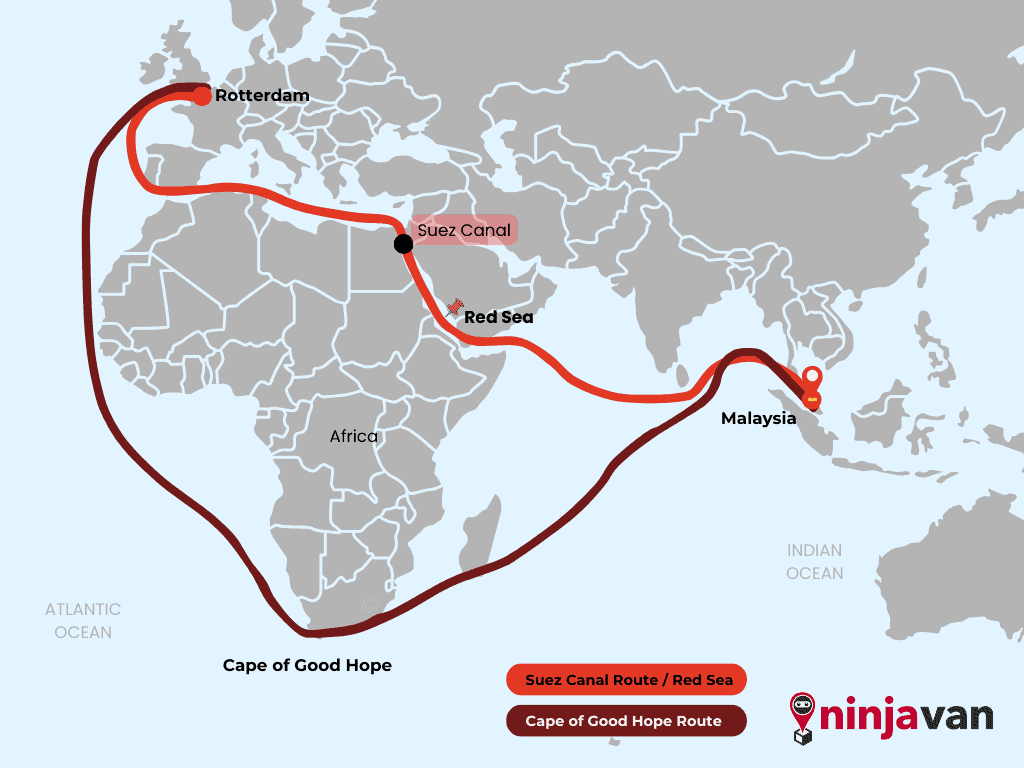

The Red Sea Attack is all about geopolitical tensions and conflicts in the Red Sea region, particularly involving countries like Yemen, Saudi Arabia, and Eritrea. These conflicts are messing with key maritime routes essential for global trade. The Red Sea connects the Mediterranean Sea via the Suez Canal to the Indian Ocean, making it a vital trade route.

Since mid-November 2023, Houthi rebels have ramped up attacks on commercial ships in the Red Sea. As a result, major shipping companies are avoiding the Red Sea and the Suez Canal, 0leading to a significant shift in shipping activities. The Red Sea is crucial for global trade, with one-third of container traffic and 12% of seaborne oil passing through it. Now, many vessels are taking the longer route around the southern part of Africa, which adds about $1 million in fuel costs per round trip.

Container ship transits in the Red Sea have dropped by 67%, and liquefied natural gas (LNG) carriers have completely stopped since January 2024. This rerouting has spiked shipping costs. For instance, shipping costs from Shanghai to Europe have more than tripled since early December 2023. The cost for a container traveling from Shanghai to Rotterdam has jumped by 158% over the past year, reaching $4,426. Plus, consumer goods in Southeast Asia are getting pricier as shipments reroute via the Cape of Good Hope.

Why Asia’s Supply Chains are Feeling the Heat

The disruptions in the Red Sea are causing a domino effect on Asia’s logistics and supply chains. About 40% of Asia-Europe trade usually goes through the Red Sea. Now, higher shipping costs and delays are affecting the entire supply chain, leading to higher consumer prices and potential inflation.

The disruptions caused by the Red Sea Crisis have significantly impacted Asia’s supply chains. Here are some key effects:

- Reroute and Shipping Time: Singapore’s Trade and Industry Minister mentioned that the recent attacks have caused some delays to Singapore’s imports from Europe. In response, major shipping lines are rerouting their trans-Pacific and Asia-Europe services via the Cape of Good Hope. This new route adds 10 to 15 days to the transit time.

- Port Congestions & Shortage of Containers: Blockages or attacks have severely disrupted port operations. Such disruptions delay the movement of containers and create bottlenecks that take time to clear, leading to a shortage of available containers for other shipping routes.

- Increased Freight Costs: The crisis has led to rerouted vessels to avoid conflict zones, resulting in longer transit times and higher shipping costs. In Malaysia, 80% of vessels are now opting for the Cape of Good Hope route, doubling freight rates and affecting trade routes to the US and Europe.

- Disruption of Food Supply: Ritesh Kumar from The Smart Cube noted that this crisis is already harming the global supply chain and could get worse. Businesses should brace for longer shipping times and higher prices for wheat, sunflower oil, and European dairy products in Southeast Asia.

Survive and Thrive: Navigating Logistical Obstacles

To navigate these challenges, businesses can adopt several strategies:

- Diversify Supply Chains & Shipping Routes: Companies should explore alternative shipping routes like the Cape of Good Hope, even though they are costlier, to avoid risks in the Red Sea. A multi-modal transportation strategy is also key to reducing reliance on sea freight. For urgent shipments, consider air freight. Start evaluating alternative transport options and their financial impact.

- Shift from Just-in-time to Just-in-case Inventory Management: Keep higher safety inventory levels to buffer against delays. Analyze historical data, understand demand variability, and plan for longer lead times. While holding more inventory costs extra, such as storage and insurance, it’s better than dealing with stockouts.

- Strategic Partnerships with Established Logistics Providers: Partner with logistics providers that have extensive networks and global partners to streamline supply chain operations. This collaboration is crucial to tap into their resources and find cost-effective and reliable shipping solutions, especially during disruptions.

Wrapping It Up

The Red Sea crisis is a significant challenge for global trade and supply chains due to longer lead times and higher costs. This crisis is likely to continue as long as geopolitical tensions persist. According to BIMCO’s forecast, it might last several months or even years, with normal shipping through the Red Sea and Suez Canal not resuming until 2025. To navigate these disruptions, businesses should adopt the strategic measures outlined in this article. Staying informed and proactive in responding to global trade issues is essential for resilience and continued success in today’s interconnected world.