If you’ve ever faced a stockout of your best-selling product during peak season or dealt with overflowing shelves of items that no one wants, you’re not alone.

Stock management is like a high-stakes juggling act — one slip, and you’re either losing customers or wasting resources.

As someone who’s navigated the messy world of retail distribution, I’ve been there and done that (probably more times than I’d like to admit).

But here’s the good news: replenishing stock doesn’t have to feel like a game of chance.

Let me walk you through my journey of learning how to replenish stock effectively and share strategies that actually work.

The “Big 3” Challenges of Traditional Stock Replenishment

Before we dive into the solutions, let’s talk about the problems — because let’s be real, understanding the struggle is half the battle.

1. The FMCG Dilemma

Fast-moving consumer goods (FMCG) are like TikTok trends — blink, and the demand changes. Managing retail distribution for FMCG is tricky because you’re balancing short shelf lives with wildly fluctuating demand. Stock too much, and you’re dealing with waste.

Stock too little, and your customers move on to the next store.

Traditional transporters or conventional lorry services can no longer keep up with this fast-moving demand. Many still rely on outdated methods, acting as middlemen rather than offering direct, tech-driven solutions.

This makes communication slow and tracking unreliable, leading to inefficiencies that retailers simply can’t afford in today’s high-speed market.

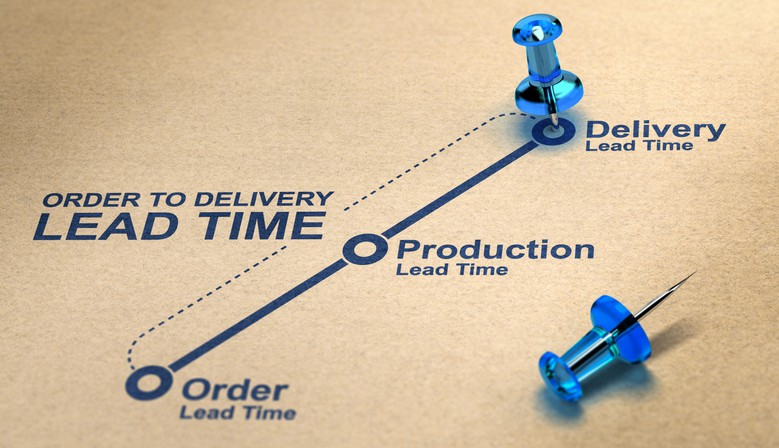

2. Long Lead Times & MOQs

Ever feel like suppliers are playing hard to get?

Long lead times and minimum order quantities (MOQs) can be a nightmare. You’re forced to order more than you need just to hit the MOQ, and by the time the stock arrives, the market might’ve already shifted.

But through this blog, I’ve learned about the benefits of no MOQ and how it can change the game for stock replenishment.

Now, I understand how to plan no-MOQ deliveries strategically, ensuring I restock only what’s needed—minimizing waste, reducing storage costs, and keeping up with ever-changing market demands.

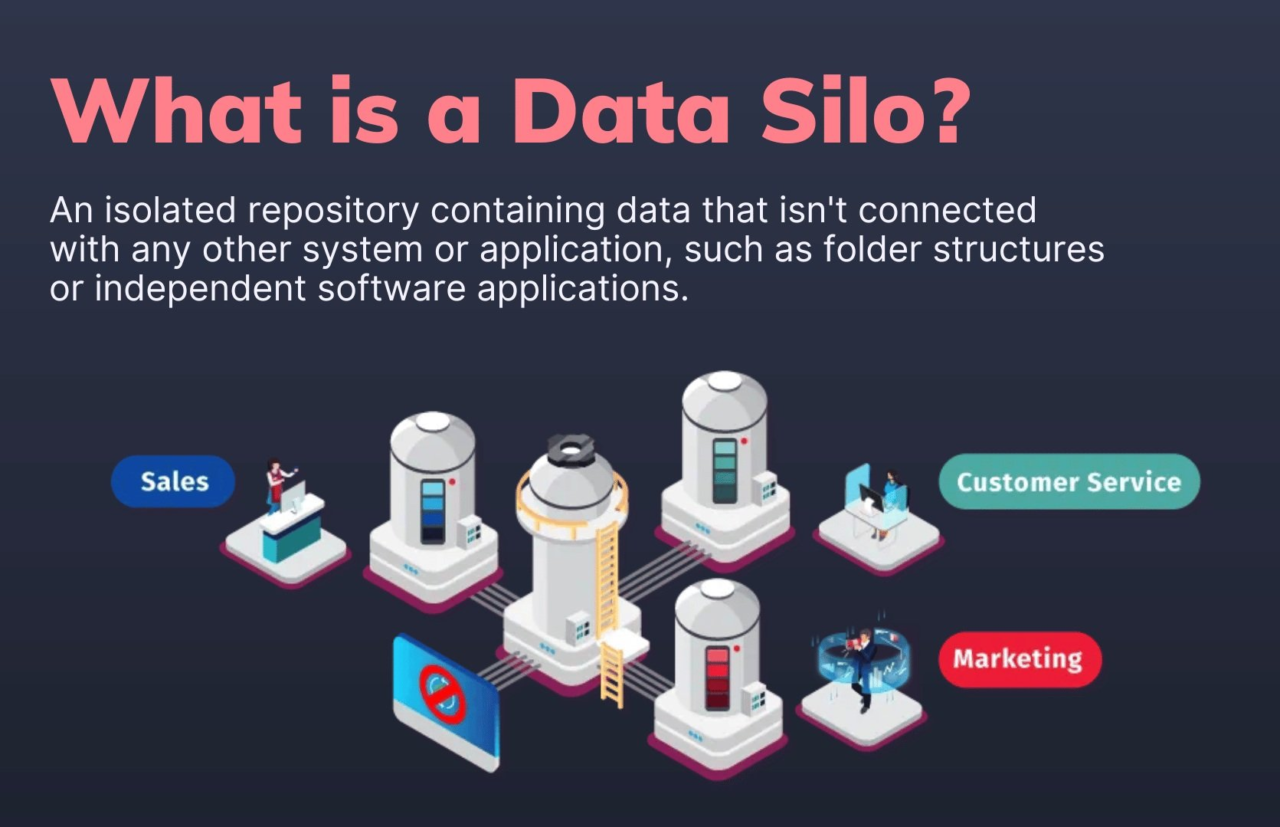

3. Data Silos

One system says you’ve got 50 units left, another says 20, and your store manager insists it’s zero.

Sound familiar? Managing inventory data across disconnected systems leads to confusion and makes it impossible to get a clear picture of your stock.

My Journey to Streamlined Stock Replenishment

Let me share a little throwback to one of my worst inventory fails: a stockout of our top-selling product right before a major holiday.

Customers were frustrated, staff were stressed, and I was scrambling to find a solution.

The “Aha!” Moment

The chaos made me realise we needed to get our act together. It wasn’t just about filling shelves; it was about understanding demand, optimising orders, and keeping the team in sync.

The Fix

I started with three key changes:

- Implementing a robust demand forecasting system to helped us predict demand using historical sales data and trends.

- Working with suppliers to negotiate better lead times and lower MOQs: Sharing forecasts and committing to consistent orders reduced inventory costs and improved stock availability.

- Streamlining our data systems to eliminate silos to give us a real-time view of inventory, reducing errors and delays.

These small changes turned out to be game-changers, laying the foundation for efficient inventory replenishment methods that I’ll break down for you next.

5 Effective Strategies for Efficient Stock Replenishment

Efficient stock replenishment isn’t rocket science, but it does require a strategic approach. Here’s what worked for me:

#1. Demand Forecasting

This is your crystal ball for stock management. Whether you use simple methods like moving averages or advanced tools like AI-based forecasting, understanding future demand is non-negotiable.

For example, during a seasonal sale, we used exponential smoothing to predict demand spikes, which helped us stay ahead of the curve.

In Malaysia, seasonal demand surges happen around major events like:

| Season / Event | Common High-Demand Products |

| Ramadan & Hari Raya Aidilfitri | High demand for food, clothing, and home essentials. |

| Chinese New Year | A spike in gifts, hampers, and festive snacks. |

| Deepavali | Increased purchases of traditional clothing, sweets, and home decor. |

| Year-End & 11.11/12.12 Sales | Electronics, fashion, and beauty products see massive surges. |

| Back-to-School Season | Stationary, uniforms, and school bags peak in demand. |

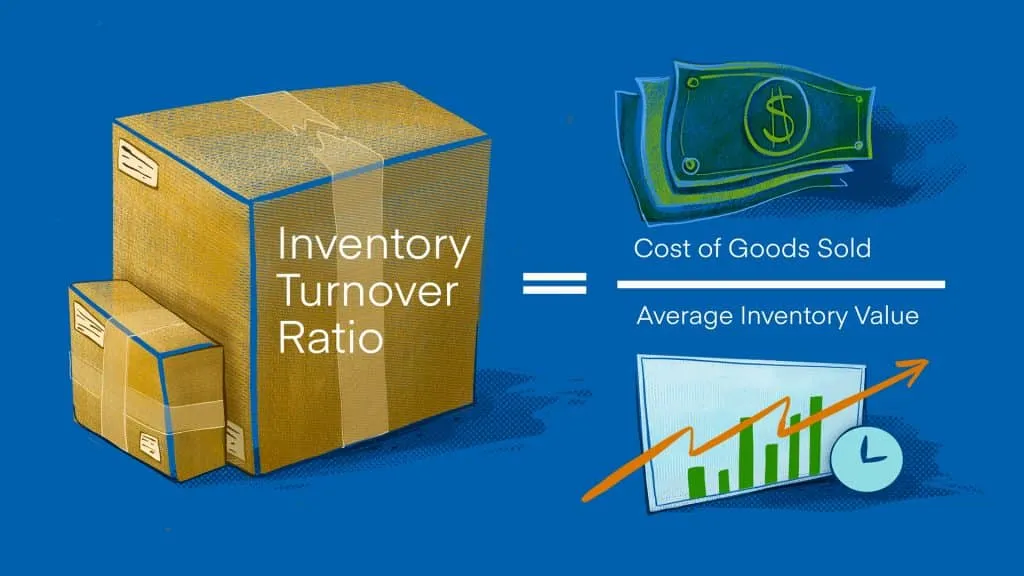

#2. Inventory Turnover Analysis

Not all products are created equal. Calculating inventory turnover (COGS ÷ average inventory) helps you figure out which items are flying off the shelves and which are collecting dust.

High turnover items? Replenish frequently.

Low turnover items? Maybe it’s time for a promotion or clearance.

However, striking a balance between the two is key.

While fast-moving products keep cash flow healthy, slow-moving items shouldn’t be completely written off. Instead, bundling them with bestsellers, offering limited-time discounts, or repositioning them in marketing campaigns can help move stagnant stock while maintaining profitability.

Effective inventory planning ensures you have the right mix of products—keeping shelves stocked with what customers want without overloading storage with what they don’t.

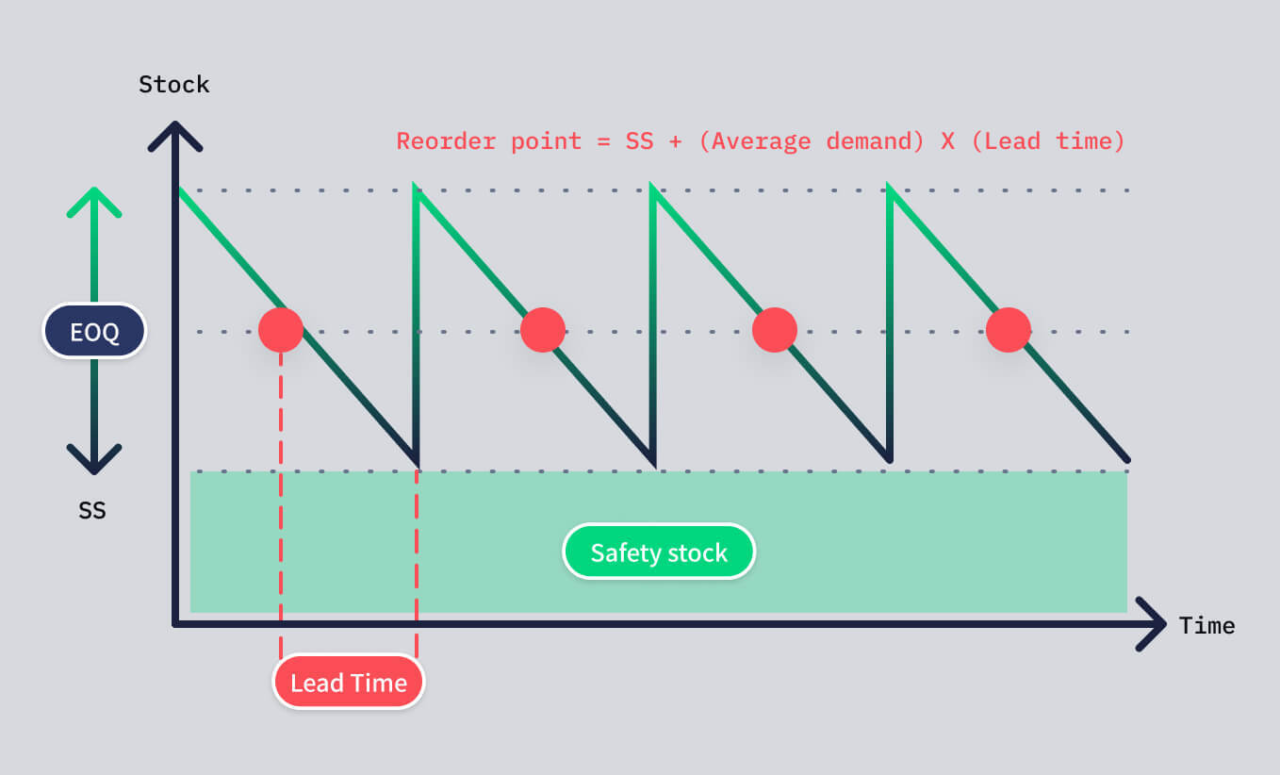

#3. Safety Stock Calculations

Safety stock is your safety net. The formula might sound boring (lead time × demand variability × service level), but trust me, it’s essential. It saved us from stockouts during unexpected surges, especially for high-demand FMCG items.

A real-life scenario? Face masks and hand sanitizers in 2020. When the pandemic hit, demand skyrocketed overnight.

Even everyday items like instant noodles, cooking oil, or diapers experience unexpected surges—think flash floods disrupting supply chains or viral TikTok trends suddenly making a product sell out.

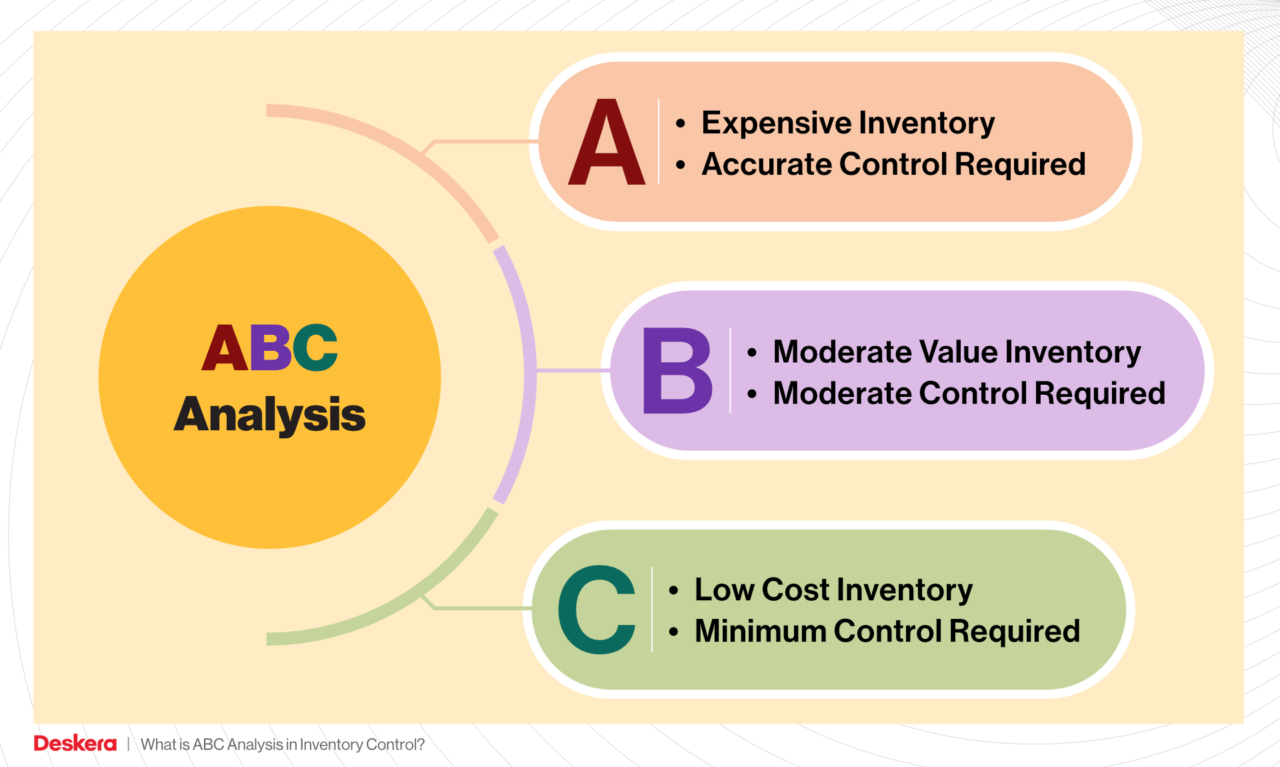

#4. ABC Analysis

This is like ranking your inventory based on importance:

- A items: High value, low quantity (e.g., premium products).

- B items: Moderate value, moderate quantity.

- C items: Low value, high quantity (e.g., staples).

Focusing your efforts on A items ensures you’re putting your energy where it matters most.

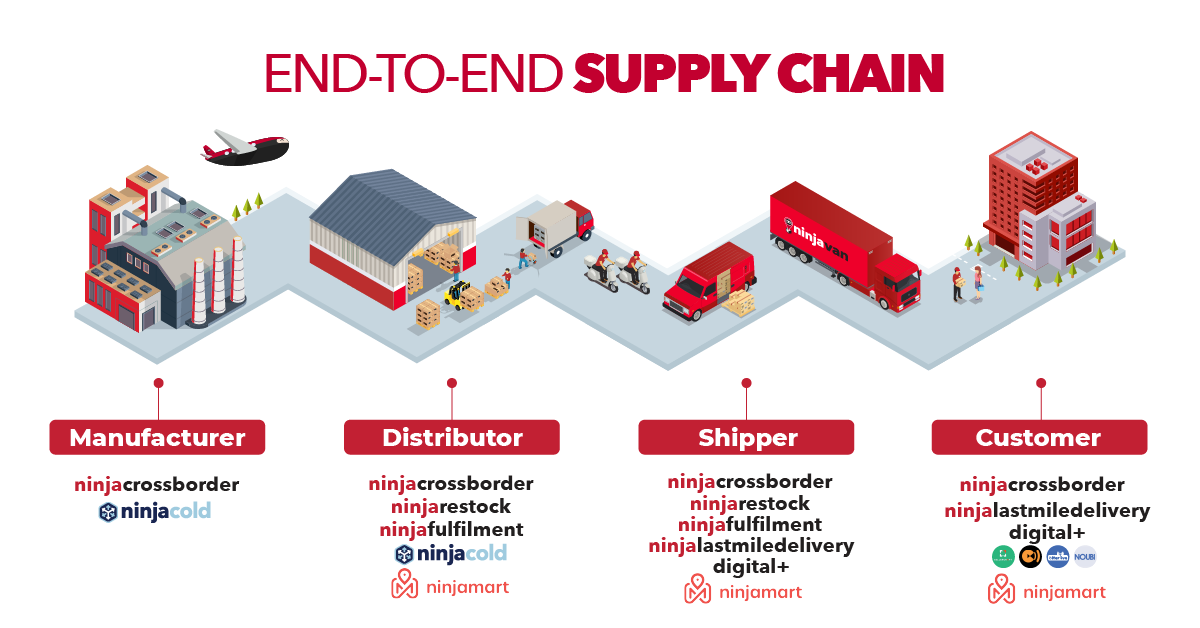

#5. 3PL Integration

Third-party logistics (3PL) providers can be lifesavers.

They handle warehousing and distribution while giving you real-time inventory data across multiple locations. We integrated a 3PL solution last year, and honestly, I haven’t looked back since.

Ninja Restock: The Solution

With Ninja Restock by Ninja Van, you’re not just solving logistics issues — you’re addressing the exact challenges that hold businesses back.

Whether it’s improving ordering process, lead time, or integrating seamlessly with third-party logistics (3PLs), Ninja Van has you covered.

Here’s how they make a difference:

| Benefit | Description |

| Save Time & Money | Eliminates costly in-house logistics setups, allowing reinvestment in growth opportunities. |

| Increase Speed & Accuracy | Integrated logistics functions improve demand forecasting and inventory management. |

| Access Instant Industry Expertise | Logistics professionals ensure compliance and efficiency, keeping you ahead of regulatory changes. |

| Expand Your Reach | Vast fulfilment networks handle local and international shipments, reducing lead-time challenges. |

If you’re looking for a service that wraps all these strategies into one neat package, Ninja Restock is the answer—an inventory assistant that never sleeps.

It solves the challenges we just talked about:

- Low MOQs and Flexible Restocking: Ninja Restock enables frequent, smaller deliveries, ensuring you always have the right stock at the right time without overburdening your cash flow.

- Integrated Data Tracking: Ninja Restock offers real-time inventory visibility and centralised tracking, eliminating the silos that disrupt your decision-making.

- Nationwide Reach: Ninja Restock’s expansive network ensures timely deliveries, helping you overcome delays caused by logistical bottlenecks.

“From Chaos to Clarity”—Revolutionise Your Stock Replenishment

So, what’s next? Take a step back, evaluate your current inventory process, and start implementing these strategies today.

Contact us today to learn how Ninja Restock’s 3PL integration can transform your inventory management!