Running a business, especially in the B2B world, means juggling a lot. But if there’s one thing that can throw a wrench in the works, it’s running out of stock.

For SMEs that rely on consistent inventory to keep customers happy, stockouts can feel like a nightmare that just won’t end. Think about it: delayed orders, lost customers, and maybe even a hit to your brand reputation. So how do you avoid the chaos? Enter proactive inventory management.

Proactive inventory management for SMEs is all about planning ahead. It’s like having an umbrella on a cloudy day — you might not need it, but if the rain comes, you’re ready. And, just like in the aviation industry, where you can’t afford to be grounded by a missing part, SMEs need to keep stock flying off the shelves (without crashing into a stockout).

With that, let’s explore how you can keep your business in the clear with these effective B2B inventory management strategies.

Understanding the Real Cost of Stockouts: Implications Beyond Lost Sales

Sure, losing a sale hurts. But the costs of stockouts go way beyond that first missed opportunity. Preventing stockouts in B2B businesses should be a top priority because those empty shelves can cost more than just a few bucks. Here’s what a stockout really means:

- Customer Dissatisfaction: When you can’t deliver, customers get frustrated. They might start to doubt your reliability, which can hurt your brand credibility in the long run.

- Potential Loss of Contracts: In B2B, one broken promise can lead to bigger problems. Businesses that can’t fulfil orders might face penalties or lose key contracts altogether.

- Hidden Costs: Think emergency restocking fees, overtime pay for staff handling the mess, and potential delays in other operations.

Consider the 2021 holiday season: amid widespread supply chain disruptions, 39% of shoppers chose to switch brands, and 32% went to alternative retailers when they encountered stockouts.

This didn’t just lead to immediate revenue losses — it also damaged long-term brand loyalty as customers sought alternatives they could rely on.

For B2B companies, such scenarios highlight the potential fallout from stockouts. Losing a client to a competitor because you couldn’t meet their needs can cost more than a single sale; it can end a business relationship entirely.

Adapting Aviation Industry’s Best Practices to B2B Inventory Management

You know how we mentioned that B2B businesses and the aviation industry are quite alike? Well, there’s actually a lot you can learn.

Just like airlines can’t afford to run out of parts and be grounded, your business can’t afford a stockout that grinds everything to a halt. So, how do airlines keep things running smoothly? Below is how you can steal a few pages from their playbook.

First, predictive analysis and demand forecasting play a crucial role. In aviation, there’s no room for guessing.

Airlines track trends and use predictive analysis to know exactly when they’ll need a part. B2B businesses can do the same.

By monitoring demand patterns and using data to forecast, you can get ahead of any potential spikes. It’s all about keeping things ready before they’re needed so you’re never caught off guard.

Next, strategic partnerships with suppliers are vital. Airlines rely on trusted suppliers to get parts on time, every time.

For B2B businesses, having that same level of reliable supplier partnerships is crucial.

Think about it: when you have a supplier who’s there when you need them most, you’re covered even during the craziest times. Building strong supplier relationships is key to maintaining optimal stock levels and avoiding those last-minute scrambles.

Finally, there’s safety stock and reorder points.

In aviation, safety stock is a non-negotiable backup. It’s their insurance policy when things go south.

For B2B businesses, keeping a buffer stock is equally essential. Safety stock is there to handle the unexpected, while reorder points make sure you know exactly when to restock. It’s all about being prepared, so you’re never left scrambling.

Building Strategic Supplier and Logistics Partnerships: A Key to Inventory Stability

We’ve talked about suppliers, but there’s another player you need in your corner: your logistics provider.

Having strong partnerships with suppliers is crucial, but building relationships with logistics companies that offer complete supply chain solutions is how you really streamline B2B supply chain processes.

To begin with, having comprehensive supply chain solutions can make all the difference.

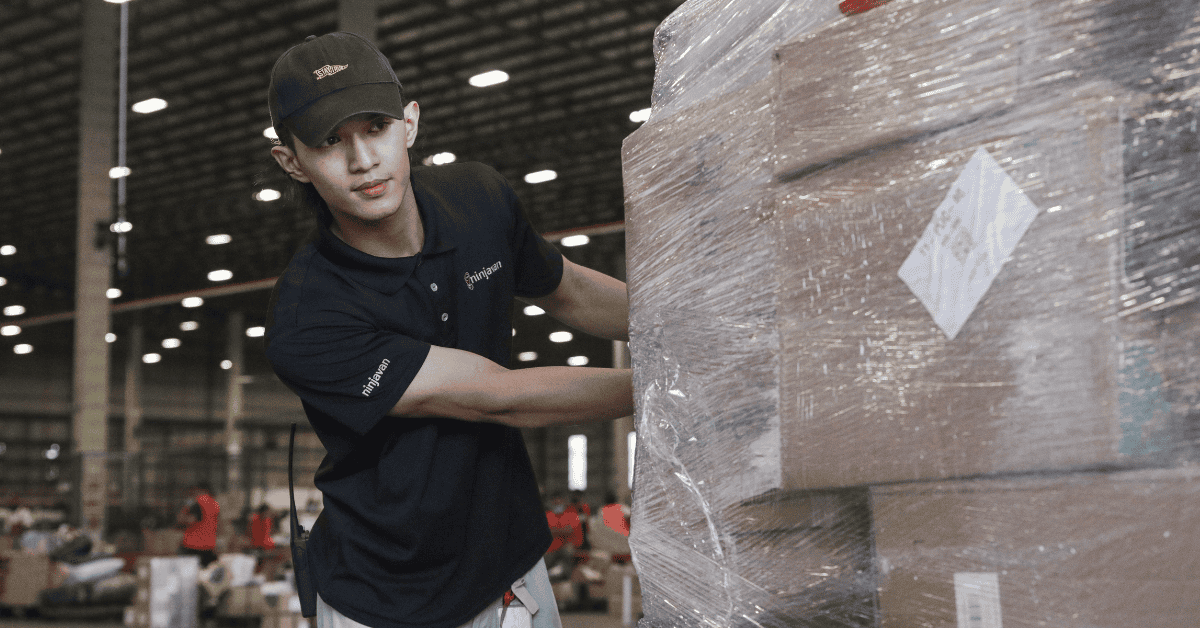

When a logistics provider can handle everything from warehousing to last-mile delivery, it takes a huge load off your plate. With reliable logistics partners, you get tailored B2B restocking services that keep your inventory moving like clockwork.

Their end-to-end support means you’re covered at every step, so you can focus on what you do best.

In addition, good logistics also help reduce stockout risks by making sure your supply chain is as efficient as possible. The smoother your supply chain, the easier it is to keep inventory at optimal levels.

Ninja Van, for instance, not only offers real-time tracking and timely deliveries but also helps you stay on top of inventory needs so that stockouts become a thing of the past.

Ninja Van’s B2B Restock: The Smart Approach to Inventory Management

If stepping up your restocking process is on your radar, Ninja Van’s B2B Restock might just be what you’re looking for. Designed with SMEs in mind, Ninja Van offers a range of services that make inventory management feel less like a chore and more like a well-oiled machine.

What Makes Ninja Van’s B2B Restock the Solution You Need?

With a full suite of services, Ninja Van’s B2B Restock is more than just a restocking service—it’s a smart approach to keeping your business ready for anything. Here’s how it works:

- Scheduled & On-Demand Restocking: Need restocks more regularly? Or dealing with sudden demand spikes? No problem. We offer both scheduled deliveries to keep your shelves steady and on-demand restocking when things get busy.

- Real-Time Inventory Tracking: Keeps you informed and helps you make better decisions without the guesswork.

- End-to-End Support: Ninja Van handles everything from warehouse to delivery, so you’re covered at every step.

Why Professionals Are Choosing Ninja Van’s B2B Restock

The perks go beyond just making restocking easier. Ninja Van’s B2B Restock is all about making your operations smarter, so you’re prepared for growth:

- Reduced Stockout Risks.

- Improved Supply Chain Efficiency: Ninja Van’s network cuts down on the usual delays and inefficiencies.

- Optimized Inventory Costs: With Ninja Van’s data-driven approach, you can avoid overstocking while still meeting demand.

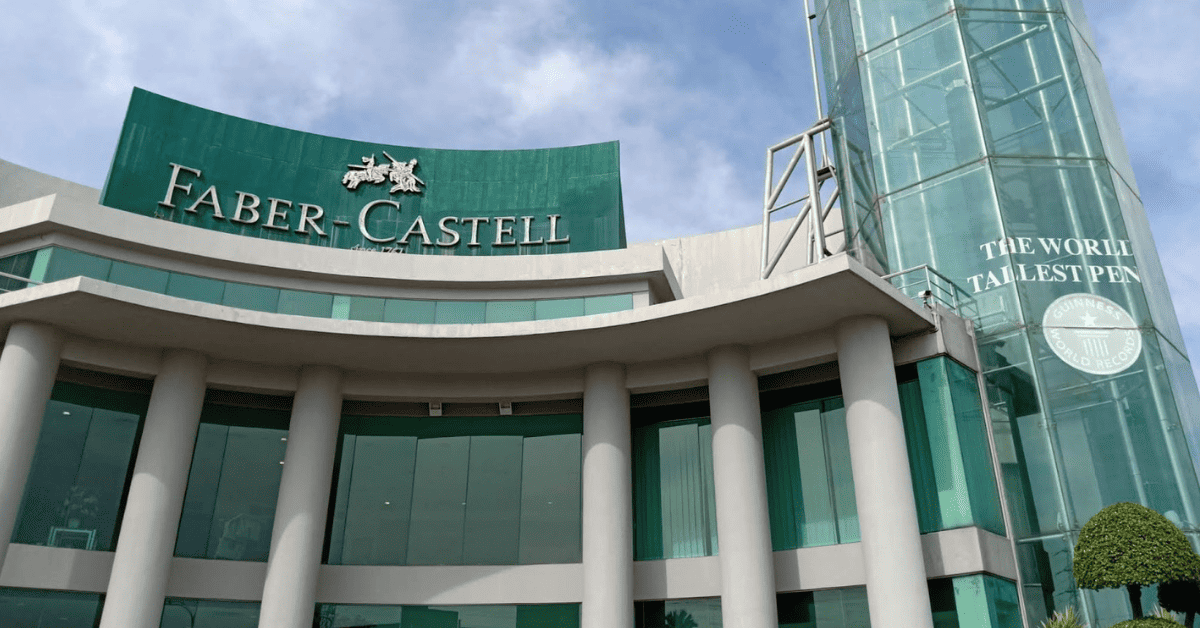

Real-World Results: Faber-Castell’s Transformation

Faber-Castell, a global leader in art and writing supplies, faced challenges in distributing products efficiently across Malaysia, especially for B2B clients in the education and corporate sectors.

Limited coverage, slow deliveries, and lack of real-time tracking impacted their ability to meet demand.

Ninja Van’s B2B Restock offered the perfect solution, providing nationwide coverage and real-time tracking that has significantly boosted Faber-Castell’s operational efficiency.

According to Loo, Warehouse Manager at Faber-Castell Malaysia:

“With their just-in-time approach, we’ve minimized inventory holding and avoided stockouts in our stores and warehouses.”

Before, Faber-Castell only had 30% visibility into their deliveries.

Now, with Ninja Van’s 100% online platform and dedicated account support, they can manage, track, and resolve delivery issues swiftly, optimizing inventory and meeting customer expectations effortlessly.

Ready to Make Inventory Management Easier?

Ninja Van’s B2B Restock is helping professionals across Malaysia simplify their operations, cut down on stock issues, and stay ready for whatever’s next.

Reach out to Ninja Van today and discover how B2B Restock can help keep your business stocked, efficient, and ready to grow.