Retailers are often confronted with challenges.

In the competitive world of retail, effective stock management is key to success—unexpected stockouts, excessive inventory holding, and rising operational costs demands for such proactiveness.

To effectively overcome these challenges, businesses must adopt innovative distribution strategies—one that provides tailored solutions specifically designed for B2B operations, with the potential to significantly enhance your retail distribution efficiency.

This post will explore 8 key strategies to optimize your distribution process utilizing Ninja Restock‘s capabilities—by way of illustration.

1. Leveraging Direct-to-Store Delivery

Conventional distribution models frequently entail intricate logistics networks, resulting in elevated costs and extended delivery timelines.

This leads to significant inefficiencies—increased transportation expenses, prolonged lead times, and a higher risk of stockouts—that therefore negatively impact profit margins and overall business growth.

Ninja Restock introduces a direct-to-store delivery system to solve:

- Elimination of superfluous warehousing expenses

- Accelerated delivery times

- Consistent inventory levels

- Simplified logistics management

2. Implementing Just-in-Time Delivery

In dynamic market conditions characterized by fluctuating demand, maintaining excessive inventory levels can pose significant challenges.

This can greatly result in substantial storage costs, increased risks of stock obsolescence and spoilage; and a significant portion of working capital being tied up in unsold goods.

@step What happens to all the unsold clothes at retail stores? 👚🤔 #stepmobile #personalfinance #learnontiktok #moneytips #genzfinance #finfluencer #moneytoks #financetok #fintok #business #money #stocks #hysa#blackcard #stepblack #creditcard

♬ original sound – Step

These inefficiencies impact profitability which hinders a company’s ability to respond effectively to changing market dynamics.

To mitigate these challenges, businesses can implement just-in-time (JIT) delivery strategies, Ninja Restock‘s key differentiator, that helps;

- Reduce storage requirements

- Enhance cash flow management

- Minimize product obsolescence

- Increase operational flexibility

3. Gain Real-Time Visibility

Effective distribution relies heavily on a deep understanding of market dynamics, customer behavior, and logistical complexities.

This knowledge enables businesses to make informed decisions regarding inventory levels, transportation routes, and fulfillment strategies—ultimately optimizing supply chain and achieving competitive advantage.

Powerful tracking system that offers real-time visibility of your inventory and delivery status benefits in:

- Live tracking updates

- Early warning for delays

- Enhanced operational efficiency

- Informed decision-making

4. Scaling Operations to Meet Peak Demand

Retail businesses operate within dynamic market environments characterized by seasonal fluctuations in consumer demand.

During peak shopping periods such as festive seasons and major sales events, the ability to effectively scale operations becomes supreme.

Failure to adequately address increased order volumes has been frequently proven to lead to significant disruptions, namely delayed deliveries, stockouts, and a decline in customer satisfaction and revenue.

With robust logistics network—Ninja Restock’s competitive advantage—is designed to help businesses scale their operations efficiently without compromising quality, including:

- Flexible delivery capacity

- Priority scheduling options

- Resource allocation during peaks

- Seamless promotional campaign support

5. Embracing Digital Transformation

In today’s fast-paced business environment, relying solely on manual processes for distribution management can lead to significant inefficiencies.

Manual data entry is prone to human error, which ties to inaccuracies in order processing, inventory management, and delivery scheduling.

Furthermore, paper-based systems can hinder data analysis and reporting, making it difficult to identify areas for improvement and make informed business decisions.

To overcome these challenges, businesses must embrace digital transformation within their distribution operations, which benefits in:

- Automated order processing

- Centralised control

- Real-time data access

- Better compliance and audit trails

6. Optimizing Cost Efficiency in Distribution Operations

Effective distribution strategies extend beyond the mere movement of goods; they encompass the optimization of logistical processes to minimize operational costs.

Optimizing logistical processes involves streamlining operations to enhance efficiency and reduce costs, including:

- Implementing route optimization software to minimize fuel consumption.

- Consolidating deliveries to improve resource utilization.

- Leveraging technology like warehouse management systems to minimise human error.

Inefficient distribution practices can lead to significant financial burdens.

Hence, the best way to enhance cost efficiency is to implement smart distribution.

👉 Interested to know how Ninja Restock optimises routing and scheduling? Contact us here!

7. Access Nationwide Coverage

Coordinating with multiple logistics providers, managing disparate service levels, and ensuring consistent delivery performance across all locations is complex and resource-intensive.

This fragmented approach can lead to increased operational costs, diminished service quality, and difficulties in maintaining consistent brand experiences for customers across different regions.

To illustrate this point—Ninja Restock’s extensive infrastructure provides reliable service across Malaysia.

Benefits of nationwide coverage:

- Uniform service standards

- Single point of contact

- Comprehensive geographical reach

- Simplified account management

8. Ensuring Accurate and Reliable Delivery Confirmation

Accurate and timely delivery confirmation is essential for maintaining accurate stock levels and ensuring customer satisfaction.

Inaccurate delivery records lead to discrepancies between actual inventory and recorded stock levels, resulting in stockouts, overstocking, and potential financial losses.

Furthermore, ambiguous delivery records can contribute to customer dissatisfaction.

Hence, that is why Ninja Restock introduces a dual confirmation system that ensures every delivery is fully documented and verified.

Key features include:

- Electronic proof of delivery

- Detailed documentation

- Reduced disputes

- Improved inventory accuracy

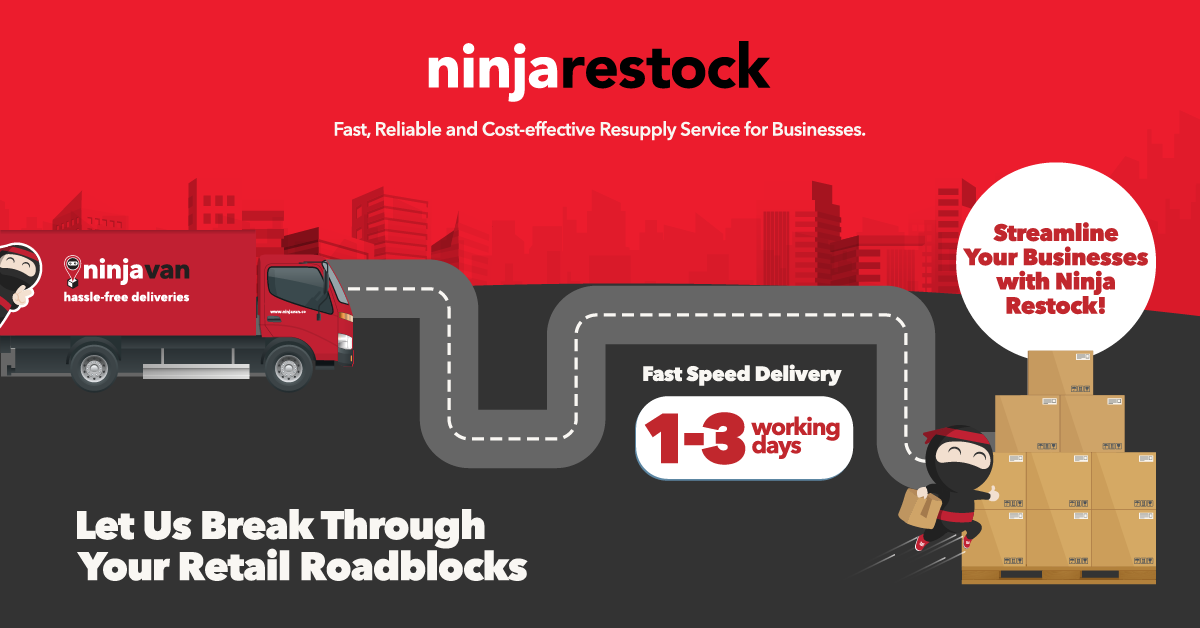

“Now is the Time!”—Implement a Profitable Distribution Strategy with Ninja Restock

Successfully transitioning to a new distribution system requires a methodical approach.

A comprehensive implementation plan should include the following key steps:

| Step | Description |

| 1. Conducting a Thorough Assessment | Assess current distribution challenges and identify areas for improvement or pain points within the system. |

| 2. Designing a Customized Solution | Tailor the distribution strategy (e.g., Ninja Restock) to address specific needs and requirements of the business. |

| 3. Implementing a Pilot Program | Test the new system on a limited scale, such as in a specific region or with select product lines. |

| 4. Continuously Monitoring and Evaluating Performance | Analyze KPIs, gather feedback, and make adjustments to optimize the system. |

| 5. Scaling the Implementation | Gradually expand the new system across the entire organization after a successful pilot phase. |

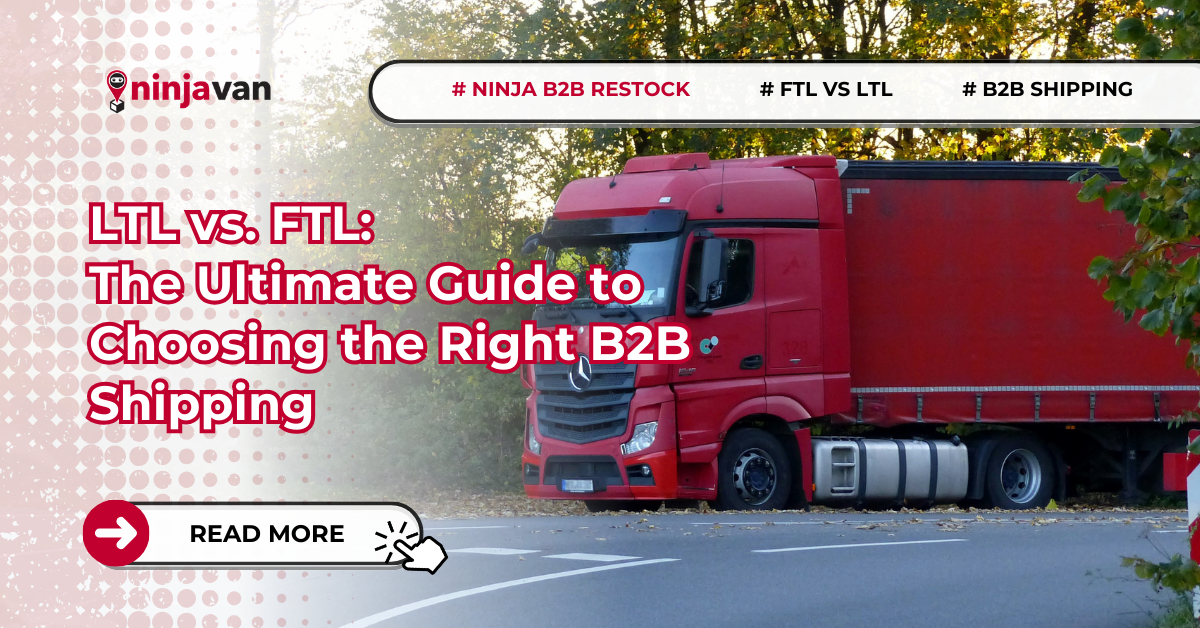

Struggling with On-Demand LTL? Let Us Fix It for You!

In today’s fast-paced market, managing on-demand less-than-truckload (LTL) logistics can be a challenge.

Fluctuating demand, limited truck capacity, and inefficient routing can disrupt your supply chain and impact your bottom line.

Ninja Restock offers a smart solution designed to streamline your LTL distribution, ensuring you only pay for the space you use and improving your overall efficiency.

Ready to optimize your logistics and tackle the complexities of on-demand LTL?

Contact us today to get valuable insights on how Ninja Restock can fix these issues and transform your supply chain.

Let’s create a solution tailored to your needs!